The performance of ethylene-vinyl acetate copolymer

Feb 28,2022

Introduction

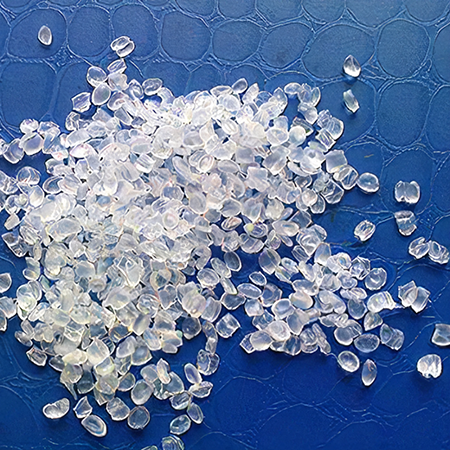

EVA is the English abbreviation of ethylene-vinyl acetate copolymer, which is a random copolymer composed of non-polar, crystalline ethylene monomer and strong polar, non-crystalline vinyl acetate monomer (also known as VA). It was first synthesized by the American scientist H.F. Mark using the low-pressure method in 1928. Later, in 1938, the British ICI Chemical Industry Company published a patent for the manufacture of EVA by high-pressure polymerization. In the early 1960s, the American DuPont Company began to have industrial products. Up to now, its application products have penetrated all aspects of people's lives, such as shoe materials, films, wires and cables, toys, hot melt adhesives, coatings and so on. Figure 1 is a physical map of EVA.

Picture 1 The physical map of EVA

The synthesis of EVA

The content of vinyl acetate (VA) in ethylene-vinyl acetate copolymer can be very wide, ranging from 5% to 95%. Different contents have different performances, so strictly speaking, there are different subdivisions. Generally speaking, EVA products refer to EVA resin, the VA content is generally 5% to 40%, most EVA manufacturers also do this, so the EVA discussed below are all EVA resins.

Regarding the synthesis process of EVA, after more than 50 years of development, there are currently four mature EVA production technologies at home and abroad: high-pressure continuous bulk polymerization, medium-pressure suspension polymerization, solution polymerization and emulsion polymerization. Among them, the solution polymerization and emulsion polymerization processes are less used, and most enterprises use the high-pressure continuous bulk polymerization process. The high pressure continuous bulk polymerization process usually adopts an autoclave reactor or a tubular reactor, and the process principle is similar to the production process of low density polyethylene (LDPE). The typical processes of the kettle method include DuPont, USI and Lyondell Basell (formerly Equistar) processes, which can produce EVA resin with a VA content of less than 40%, and the single-pass conversion rate is 10% to 20%; the typical processes of the tubular method are Basf, Imhausem /Ruhrchemie, Basell's Lupotech process, etc., generally produce EVA resin with VA content less than 30%, and the one-way conversion rate is 25%~35%. Since the polymerization reaction mechanism of EVA under high pressure and high temperature is basically the same as that of LDPE, the difference between EVA products produced by autoclave reactor and tubular reactor is similar to the difference of LDPE produced by these two processes.

Structure and Performance

Compared with PE, EVA reduces crystallinity, improves flexibility, impact resistance, and improves filler mixing and heat sealing due to the introduction of vinyl acetate monomer into the molecular chain. Generally, the density is between 0.91 and 0.93. , good transparency and gloss. The performance of EVA resin mainly depends on the vinyl acetate content (VA content) and melt flow rate (MFI) in the copolymer. EVA products have good flexibility, low temperature resistance, impact strength, environmental stress crack resistance, good optics, good air permeability, general mechanical properties, and poor insulation properties in a wide temperature range.

The processing and molding of EVA

EVA is a thermoplastic polymer, so it can be used in injection molding, extrusion, blow molding, calendering, rotomolding, vacuum thermoforming, foaming, coating, heat sealing, welding and other processing and forming processes. EVA molding process temperature is low (160-200 ℃), the range is wide, its mold temperature is low (20-45 ℃), the material should be dried before processing (drying temperature 65 ℃). The mold temperature and material temperature are not easy to be too high during EVA processing, otherwise the surface will be rough (not smooth). EVA products are easy to stick to the front mold, and it is better to make a buckle type at the cold material hole of the main channel of the nozzle. It is easy to decompose when the temperature exceeds 250℃. EVA should use the process conditions of "low temperature, medium pressure and medium speed" to process products.

The application of EVA

Shoe material is the most important application field of EVA resin in my country. In the EVA resin used in shoe materials, the vinyl acetate content is generally 15% to 22%. Because resin blended foam products have the properties of softness, good elasticity and chemical corrosion resistance, they are widely used in the soles and interior materials of medium and high-end travel shoes, hiking shoes, slippers and sandals; in addition, this material is also used in In the field of sound insulation boards, gymnastics mats and sealing materials.

The main use of EVA film is to produce functional shed film. Functional shed film has high weather resistance, anti-fog droplet and thermal insulation properties. Since polyethylene is not polar, even if a certain amount of anti-fog droplet agent is added, its anti-fog droplet performance can only be maintained for about 2 months; The shed film made of adding a certain amount of EVA resin not only has a high light transmittance, but also has a great improvement in the anti-fog droplet performance, which generally lasts for more than 4 months. In addition, EVA can also be used to produce packaging films, medical films, lamination films, casting films, etc.

With the continuous development of computer and network engineering, people use more and more halogen-free flame retardant cables and silane cross-linked cables for the safety of computer rooms. Because EVA resin has good filler inclusion and cross-linkability, it is widely used in halogen-free flame retardant cables, semiconductor shielded cables and two-step silane cross-linked cables. In addition, EVA resin is also used to make some special cable jackets. In the EVA resin used in wire and cable, the vinyl acetate content is generally 12% to 24%.

The hot melt adhesive with EVA resin as the main component, because it does not contain solvent, does not pollute the environment and has high safety, it is very suitable for automated assembly line production. In recent years, it has widely replaced traditional phenyl glue, so it is widely used in books wireless Bookbinding, furniture edging, assembly of automobiles and household appliances, shoemaking, carpet coating and anti-corrosion coating of metals. Hot melt adhesives mainly use varieties with vinyl acetate content ranging from 25% to 40%. Although there are products of this brand in China, production has not been arranged for a long time, so all of them are occupied by imported materials.

Renference

1 Qi Zong, Xue Ping, Ding Jun, et al. Properties of ethylene-vinyl acetate copolymer resin modified natural wood powder[J]. China Plastics, 2008, 22(2):4.

- Related articles

- Related Qustion

Naphthalene (CAS No: 91-20-3), the simplest bicyclic aromatic ring, is conventionally derived from coal tar. It is a white solid material with strong pungent odour. Naphthalene was first discovered by....

Feb 28,2022APIDXSORB 1577, chemical name UV-1577; 2-(4,6-Diphenyl-1,3,5-triazin-2-yl)-5-[(hexyl)oxy]-phenol, is used as a light stabilizer/UV absorber for polyethylene phthalate polymers intended for use in contact with food.....

Mar 2,2022Catalyst and AuxiliaryEthylene-vinyl acetate copolymer

24937-78-8You may like

Ethylene-vinyl acetate copolymer manufacturers

- Ethylene-vinyl acetate copolymer

-

- $1808.00 / 1ton

- 2024-04-30

- CAS:24937-78-8

- Min. Order: 1ton

- Purity: 99%

- Supply Ability: 8000ton

- Ethylene-vinyl acetate copolymer

-

- $500.00 / 1Tons

- 2024-04-30

- CAS:24937-78-8

- Min. Order: 1Tons

- Purity: 99%

- Supply Ability: 200Tons

- Ethylene-vinyl acetate copolymer

-

- $1.00 / 1KG

- 2024-04-25

- CAS:24937-78-8

- Min. Order: 1KG

- Purity: 99.91%

- Supply Ability: 200000